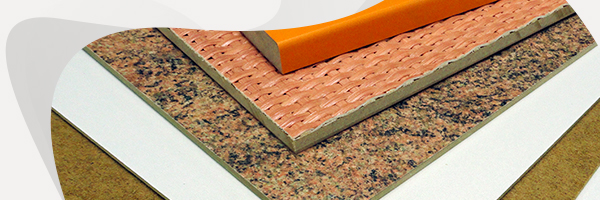

Plywood: Plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which include medium-density fibreboard (MDF), oriented strand board (OSB) and particle board (chipboard)

Solid wood is a term most commonly used to distinguish between ordinary lumber and engineered wood, but it also refers to structures that do not have hollow spaces. Engineered wood products are manufactured by binding together wood strands, fibres, or veneers with adhesives to form a composite material. Engineered wood includes plywood, oriented strand board (OSB) and fiberboard. The fact that a product is made from solid wood is often touted in advertisements.

Particle board, also known as chipboard or low-density fiberboard, is an engineered wood product manufactured from wood chips and a synthetic resin or other suitable binders, which is pressed and extruded.[1] Particle board is often confused with oriented strand board (OSB) (also known as flakeboard, waferboard, or chipboard), a fiberboard that uses machined wood flakes and offers more strength.

MDF and HDF – or Medium-Density Fiberboard and High-Density Fiberboard – are two of the trendiest materials in woodworking these days. They're both engineered by combining wood fibre and glue under immense pressure and heat and are a suitable alternative to real wood.

Lamination is the technique/process of manufacturing a material in multiple layers so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties by using different materials, such as plastic.

In woodworking, veneer refers to thin slices of wood and sometimes bark, usually thinner than 3 mm, that typically are glued onto core panels to produce flat panels such as doors, tops and panels for cabinets, parquet floors and parts of furniture. They are also used in marquetry.

Hardware products are generally categorized as products/tools used in construction and home improvement. These can include building materials, fasteners, power tools, hinges, locks, keys, plumbing supplies, cleaning supplies, electrical supplies, tools, paint, housewares, garden products, and lawn products

To clean furniture hardware, you need to establish the material of which it is made from.

To clean wooden furniture hardware such as wooden dowels, mouldings and corbels, use a mixture of water and vinegar. To clean brass furniture hardware such as brass handles and knobs use a mixture of water and baking soda. To clean copper furniture hardware such as copper door knobs and cabinet hinges use a mixture of lemon, ketchup or vinegar. To clean ceramic furniture hardware, such as ceramic door and drawer knobs, simply wipe with a damp cloth.

To remove rust from metal furniture hardware, leave it to soak in a solution of vinegar or lemon juice and borax. Once cleaned, wipe down with a dry cloth to remove any residue.

You can paint furniture hardware no matter the material, but we recommend always choosing specialist paints from a hardware store.

You can paint furniture hardware how you would paint any other piece of furniture. Choose smaller brushes to suit the size of the hardware, and cover holes with painter’s tape to prevent it from damage. Wooden furniture hardware suits gloss paints as it makes them easier to clean, and metal always needs a primer to ensure the paint doesn’t flake.